Fasteners and Machining: Tailored Solutions for each Manufacturing Need

Wiki Article

Browsing the World of Fasteners and Machining: Strategies for Accuracy and Rate

In the complex realm of fasteners and machining, the quest for accuracy and speed is a perpetual difficulty that demands careful focus to detail and calculated planning. From comprehending the varied array of bolt kinds to selecting ideal products that can withstand extensive needs, each action in the process plays a crucial role in accomplishing the wanted outcome. Accuracy machining strategies further raise the intricacy of this craft, requiring a delicate equilibrium in between technological knowledge and innovative methods. As we dig right into the strategies that can improve both rate and effectiveness in this domain name, the interaction between quality assurance procedures and functional quality arises as a crucial centerpiece.Understanding Bolt Types

When choosing fasteners for a project, recognizing the various types readily available is vital for making sure optimum efficiency and dependability. Bolts are utilized with nuts to hold products together, while screws are flexible fasteners that can be made use of with or without a nut, depending on the application. Washing machines are necessary for distributing the load of the bolt and avoiding damage to the product being attached.

Selecting the Right Products

Understanding the significance of selecting the appropriate materials is paramount in guaranteeing the optimal performance and dependability of the selected bolt kinds discussed previously. When it pertains to bolts and machining applications, the product selection plays an essential function in establishing the total strength, sturdiness, rust resistance, and compatibility with the desired setting. Various products supply differing buildings that can considerably impact the performance of the fasteners.Common materials utilized for fasteners include steel, stainless steel, aluminum, brass, and titanium, each having its one-of-a-kind toughness and weak points. Steel is renowned for its high stamina and longevity, making it ideal for a vast array of applications. Stainless-steel supplies excellent corrosion resistance, perfect for settings susceptible to moisture and chemicals. Aluminum is lightweight and corrosion-resistant, making it ideal for applications where weight decrease is important. Brass is typically chosen for its visual allure and exceptional conductivity. Titanium is understood for its extraordinary strength-to-weight ratio, making it ideal for high-performance applications. Picking the appropriate product includes thinking about factors such as toughness demands, environmental conditions, and spending plan restrictions to ensure the preferred performance and long life of the fasteners.

Precision Machining Techniques

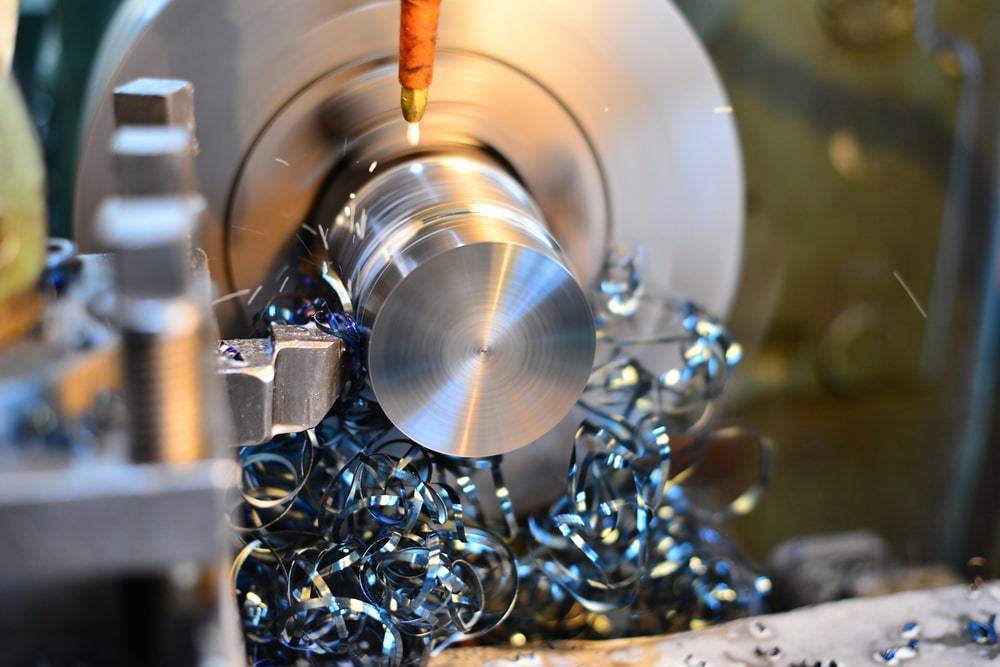

In addition to CNC machining, various other precision methods like grinding, transforming, milling, and drilling play crucial roles in fastener manufacturing. Grinding helps accomplish great surface area finishes and limited dimensional resistances, while turning is commonly used to produce round components with accurate sizes. Milling and exploration operations are necessary for forming and creating holes in bolts, guaranteeing they meet precise specs and feature correctly.

Enhancing Speed and Effectiveness

To maximize fastener production processes, it is important to streamline operations and carry out reliable approaches that complement precision machining strategies. One vital strategy for improving speed and effectiveness is the execution of lean manufacturing principles. By decreasing waste and concentrating on continual renovation, lean practices assist maximize and eliminate bottlenecks process. In addition, buying automation modern technologies can substantially boost production rate. Automated systems can take care of repeated jobs with accuracy and rate, allowing employees to concentrate on even more facility and value-added tasks. Taking On Just-In-Time (JIT) supply administration can likewise enhance efficiency by making sure that the ideal materials are available at the right time, minimizing excess supply and lowering preparations. Promoting a culture of collaboration and interaction among team participants can enhance overall performance by advertising transparency, analytic, and advancement. By combining these approaches, makers can accomplish an equilibrium between rate and accuracy, ultimately enhancing their competitive side in the fastener sector.High Quality Control Actions

Executing strenuous quality assurance steps is critical in guaranteeing the dependability and uniformity of fastener products in the manufacturing procedure. Quality control steps include numerous stages, beginning with the choice of raw products to the last inspection of the completed bolts. One basic aspect of quality assurance is performing extensive product inspections to verify compliance with specs. This includes analyzing factors such as material toughness, structure, and sturdiness to guarantee that the fasteners meet industry criteria. In addition, monitoring the machining refines is vital to promote dimensional precision and surface area finish quality. Utilizing innovative modern technology, such as automatic assessment systems and precision measuring tools, click resources can boost the precision and effectiveness of top quality control treatments.Regular calibration of devices and equipment is imperative to preserve uniformity in production and make sure that bolts meet the necessary resistances. Executing rigorous protocols for determining and addressing problems or non-conformities is crucial in preventing substandard items from entering the market. By developing an extensive high quality control structure, manufacturers can support the track record of their brand name and deliver fasteners that satisfy the highest possible standards of performance and toughness.

Verdict

In why not check here the intricate realm of fasteners and machining, the quest for precision and speed is a perpetual challenge that demands meticulous attention to detail and strategic planning. When it comes to fasteners and machining applications, the material choice plays an essential function in establishing read more the total toughness, longevity, deterioration resistance, and compatibility with the desired setting. Precision machining includes numerous innovative approaches that make certain the tight tolerances and requirements needed for fasteners.In addition to CNC machining, various other accuracy methods like grinding, turning, milling, and exploration play essential functions in fastener production.To maximize fastener production procedures, it is necessary to enhance operations and implement reliable methods that match precision machining methods.

Report this wiki page